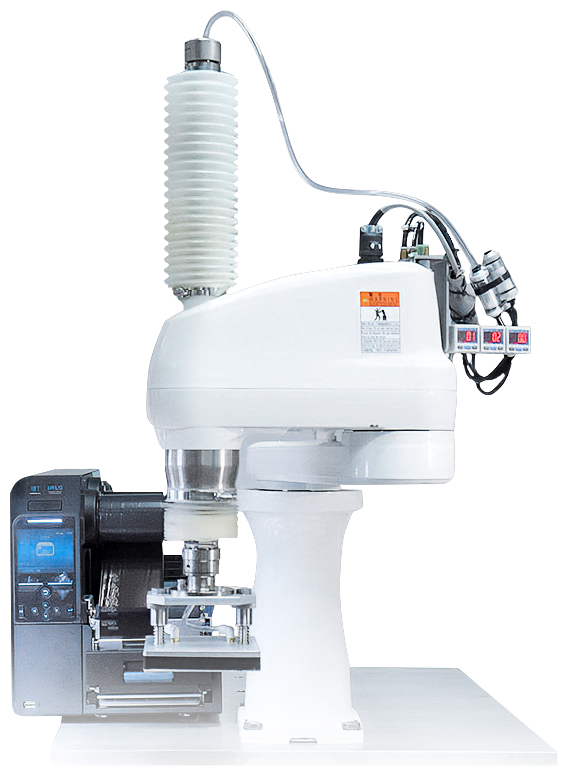

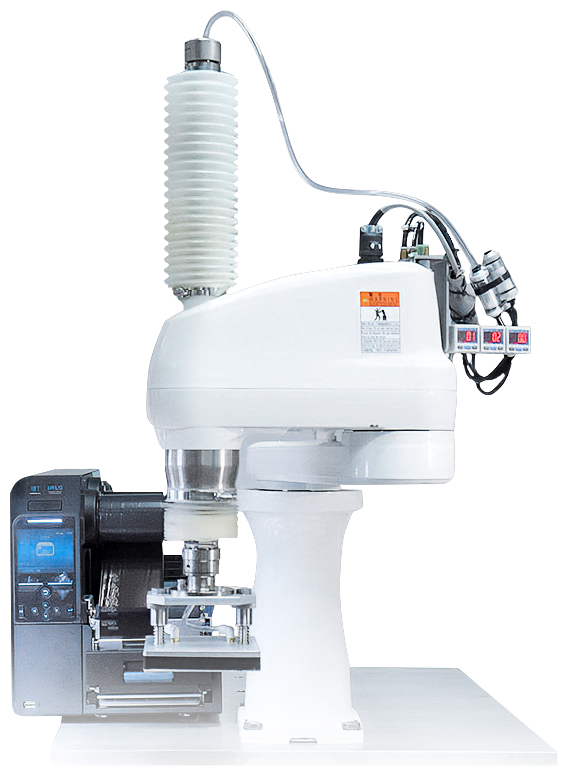

Provide an all-in-one artificial intelligence labeling solution with a robot to triple your productivity, free up 70% of your manpower in maximum, and eliminate human errors, but with lower cost.

Provide an all-in-one artificial intelligence labeling solution with a robot to triple your productivity, free up 70% of your manpower in maximum, and eliminate human errors, but with lower cost.